- Home

- Blog

- New Cutting-Edge Blade Technology Unveiled: Revolutionizing the Cutting Industry" Rewritten: "Revolutionary Blade Technology Unveiled: Transforming the Cutting Industry

New Cutting-Edge Blade Technology Unveiled: Revolutionizing the Cutting Industry" Rewritten: "Revolutionary Blade Technology Unveiled: Transforming the Cutting Industry

By:Admin

The new line of blades incorporates cutting-edge technologies and advanced materials to ensure maximum precision and efficacy. Designed to meet the evolving needs of industries such as manufacturing, construction, and healthcare, these blades offer numerous advantages over traditional cutting tools. Their unique features and capabilities significantly enhance productivity, safety, and performance across a wide range of applications.

One of the key highlights of the latest blades is their exceptional cutting efficiency. Equipped with state-of-the-art sharpening techniques and ultra-sharp edges, they provide faster and smoother cuts, reducing production time and enhancing overall efficiency. This enables industries to meet growing demands while maintaining superior quality standards.

In addition to their cutting efficiency, [Company Name]'s blades are also recognized for their exceptional durability. Crafted using high-quality materials like titanium, tungsten carbide, and diamond, these blades are built to withstand even the most demanding tasks. This robust construction ensures longevity, reducing the frequency of blade replacements and minimizing operational costs.

Furthermore, [Company Name]'s blades prioritize safety without compromising on performance. Incorporating various safety features, such as anti-kickback designs and reinforced blade bodies, they minimize the risk of accidents during cutting operations. This not only safeguards workers but also ensures uninterrupted workflow, reducing downtime caused by potential injuries.

To cater to diverse customer needs, [Company Name] offers a wide range of blades tailored for specific applications. Whether it's cutting through tough materials like concrete and metal or performing delicate surgeries, customers can choose from a comprehensive selection of blades specifically designed for each task. This versatility allows industries to optimize their operations and achieve exceptional results across various sectors.

Apart from their superior product offerings, [Company Name] prides itself on its commitment to sustainability and environmental responsibility. Recognizing the global need for eco-friendly manufacturing, the company has implemented modern production practices to minimize waste generation and reduce its carbon footprint. By choosing [Company Name]'s blades, businesses can contribute to a greener future while enjoying the benefit of cutting-edge technology.

Beyond its dedication to manufacturing excellence, [Company Name] also places great emphasis on customer satisfaction. The company's team of highly skilled professionals provides comprehensive support to assist customers in selecting the right blades for their specific requirements. Additionally, their unparalleled after-sales service ensures prompt assistance and guidance, guaranteeing optimal performance and customer satisfaction.

Looking ahead, [Company Name] plans to continue its focus on research and development to further enhance the capabilities of its blades. By investing in new technologies, materials, and manufacturing processes, the company aims to stay at the forefront of the industry and offer cutting solutions that surpass customer expectations.

In conclusion, [Company Name] is revolutionizing the cutting industry with its latest range of innovative and high-performance blades. Backed by cutting-edge technologies, superior materials, and a commitment to customer satisfaction, these blades offer enhanced cutting efficiency, durability, and safety. With [Company Name], customers can expect exceptional results across various industries, while contributing to a more sustainable future.

Company News & Blog

Top Quality Earthmoving Parts for All Your Heavy Machinery Needs" can be rewritten as "Reliable Earthmoving Parts for Your Heavy Equipment Needs

Earthmoving Parts: Leading the Way in Quality Construction EquipmentEarthmoving Parts is a leading name in the world of construction equipment. Established over a decade ago, the company has become one of the most trusted and reliable providers of high-quality earthmoving machinery and spare parts.At Earthmoving Parts, we take pride in providing our clients with the best quality equipment and parts that are tailored to their individual needs. We know that reliable machinery is essential for the success of any construction project, and that’s why we are committed to maintaining the highest standards of product quality.We have an extensive range of products available to cater to a variety of construction needs. Whether you are looking for excavators, bulldozers, wheel loaders, backhoe loaders, or any other type of earthmoving equipment, we have got you covered. All of our products are tailored to meet industry standards, and we have rigorous testing and quality control measures in place to ensure that our clients receive only the best quality products.At Earthmoving Parts, we also specialize in providing genuine and high-quality spare parts for all types of earthmoving equipment. We understand that malfunctioning equipment can cause serious delays on construction sites, and that’s why we maintain a wide range of spare parts in our inventory to ensure that our clients can get their equipment up and running as quickly as possible. Our range of spare parts includes genuine parts for all major brands, ensuring that clients can always find the parts they need, regardless of the type of machinery they are using.In addition to our high-quality products, we take pride in our commitment to outstanding customer service. We understand that our clients’ needs are diverse and can arise at any time, which is why we have a dedicated customer support team available to assist with any inquiries or concerns. Our knowledgeable team is always on hand to assist clients with selecting the right products for their construction needs and ensuring that they receive prompt and efficient service.At Earthmoving Parts, we are also committed to minimizing our impact on the environment. We understand the importance of preserving the environment for future generations and have taken various measures to ensure that our business practices reflect this commitment. We maintain rigorous quality control measures to ensure that our products meet industry standards for emissions and we take care to minimize our carbon footprint through responsible waste management practices.In conclusion, Earthmoving Parts has established itself as a world-renowned provider of high-quality construction equipment and spare parts. Our commitment to quality, reliability, and customer service has seen us grow into a leading name in the industry. We are committed to maintaining the highest standards of product quality, customer service, and environmental sustainability, and we look forward to continuing to provide our clients with the best quality products in the industry.

Huge Excavator Attachment Takes on Tough Demolition Jobs with Ripper Shank

Ripper Shank for Excavator: Maximize Your Digger's PotentialFor construction companies, excavators are a must-have equipment. It provides cutting-edge capabilities when it comes to site leveling, earth excavation, and rock breaking. However, without the right attachments, an excavator's potential is limited. This is where the Ripper Shank for Excavator comes into play.The Ripper Shank is a powerful attachment that increases the versatility of excavators. It is designed to handle tough ground conditions and efficiently rip through soil and rock. Its primary purpose is to break up hard material, making excavation smoother and efficient. Its design maximizes the power of excavators, making it ideal for a variety of construction projects.The Ripper Shank for Excavator can be used for various tasks, including breaking up hard soil, ripping up rocks, and trenching. As a result, it saves time and reduces labor costs, making it an efficient alternative to regular excavation tools. Additionally, it can handle ditches and trenches with ease without damaging the surrounding earth, meaning there is minimal cleanup required. With its durable structure, the Ripper Shank can withstand heavy-duty workloads, guaranteeing reliability and efficiency even under the most demanding conditions. It is designed to be compatible with a variety of excavator models, and it can be attached and detached with ease, improving the vehicle's efficiency and versatility.Introducing our ProductOur company has been in the manufacturing business for over five decades. We specialize in the production of high-quality earth-moving equipment. We take pride in being a reliable partner for construction companies by consistently providing top-level machinery that meets their needs.One of our flagship products is the Ripper Shank for Excavator, which has been designed to increase excavator productivity. Our team has extensive experience in the development of earth-moving equipment, and we have dedicated ourselves to creating superior digger attachments. We always put our client's needs first, which is why we have developed the Ripper Shank that not only meets their expectations but exceeds them.The Ripper Shank will add value to your excavator, making it more versatile and productive. Each Ripper Shank is carefully crafted with premium materials, and we oversee the production process to ensure it meets the highest quality standards. We maintain a rigorous inspection process to guarantee that each unit that leaves our manufacturing line will provide efficient service to our clients.Why Choose UsWe understand the importance of an excavator in your construction endeavor. Hence, our team of experts have worked tirelessly to create machinery attachments that are up to the mark. When talking about the Ripper Shank for Excavator, we pride ourselves on its ruggedness and dependability. It can handle even the most demanding tasks, resulting in faster and more efficient work output. Safety is a crucial aspect of construction work, and we understand the significance of a secure working environment. Our Ripper Shank attachment is designed to minimize the risk of accidents by reducing the need for labor-intensive manual digging. This limits the likelihood of injury to the operator and surrounding personnel.We are committed to providing excellent customer service. In addition to supplying high-quality machinery, we have an excellent support team that is always ready to address all client queries. We make sure to provide ongoing assistance and technical support for our products, ensuring that our clients can enjoy their machines with peace of mind.ConclusionThe Ripper Shank for Excavator is a versatile attachment that can make your equipment's operation smoother and more productive. With reliable construction equipment like the Ripper Shank, your project can be completed faster and more efficiently, leaving you time to focus on other aspects of the project. Our company prides itself on producing high-quality machinery and serving our clients with excellent customer support. Our Ripper Shank for Excavator is a game-changer in the earth-moving industry, and our clients can be sure of the quality and reliability of our products.

Maximize Road Efficiency with Quality Cutting Edges

Title: Innovative Road Grader Cutting Edges Revolutionize Construction IndustryIntroduction:The construction industry is constantly evolving, and one company has taken a giant leap forward with its revolutionary road grader cutting edges. These cutting-edge tools, developed by a leading manufacturer, have transformed the way road grading is carried out, significantly improving efficiency and precision. By incorporating advanced technology and superior design, they have become an essential asset in the arsenal of construction companies worldwide.Body:1. The Importance of Road Grader Cutting Edges in Construction:Road graders are crucial machines used in the construction industry for grading and leveling surfaces. However, the cutting edges of these graders can significantly impact their performance. Therefore, utilizing high-quality cutting edges ensures enhanced productivity, reduced maintenance costs, and superior results. The introduction of these innovative cutting edges has become a game-changer.2. Unmatched Durability and Reliable Performance:The road grader cutting edges developed by this renowned manufacturer are crafted from the highest quality materials, such as hardened steel alloys. This ensures exceptional strength, longevity, and resistance against wear and tear, even in demanding working conditions. With these cutting edges, construction companies can achieve consistent and efficient grading operations throughout the lifespan of the grader.3. Advanced Design for Enhanced Efficiency:A defining feature of these cutting edges is their advanced design. The manufacturer has employed cutting-edge technology and engineering expertise to create an optimized cutting profile that minimizes surface damage while efficiently removing unwanted materials. The innovative shape reduces resistance, resulting in improved fuel efficiency and reduced operator fatigue. These design enhancements translate into significant cost savings and increased productivity for construction companies.4. Versatility for Various Applications:The company understands that road grading requirements can vary greatly depending on the project and environmental conditions. To cater to diverse construction needs, they offer a wide range of cutting edge models, each designed to excel in different scenarios. Whether it's a highway construction project or a small-scale infrastructure development, these cutting edges provide tailored solutions to ensure optimal performance in any situation.5. Easy Installation and Maintenance:Recognizing the need for efficiency in the construction industry, the company has ensured that their cutting edges are designed for quick and hassle-free installation. Similarly, maintenance routines are simplified, enabling construction crews to minimize downtime and maximize project productivity. Quick-change systems, durable locking mechanisms, and helpful support guides ensure that these cutting edges can be installed or replaced efficiently.6. Commitment to Sustainability:Apart from their exceptional performance, the company's cutting edges align with the sustainable practices increasingly prioritized in the construction industry. The extended lifespan of these cutting edges minimizes waste and reduces the carbon footprint associated with frequent replacements. By investing in these cutting-edge tools, construction companies contribute to a more environmentally friendly future.7. Global Reach and Positive Customer Response:Recognized worldwide for their outstanding quality and performance, the company has established a strong global presence. Countless construction companies have experienced the benefits of these cutting edges and commend their effectiveness and durability. Positive customer testimonials reinforce the manufacturer's commitment to providing cutting-edge solutions that meet the evolving demands of the construction industry.Conclusion:The introduction of these innovative road grader cutting edges has revolutionized the construction industry, offering superior durability, efficiency, and versatility. With advanced design features and tailored solutions, construction companies can now achieve exceptional results while keeping costs low. The global success and positive customer response highlight the effectiveness of these cutting edges in enhancing productivity and delivering exceptional road grading outcomes. As the construction industry continues to evolve, these cutting-edge tools will remain essential elements, ensuring efficient and precise road grading operations.

Enhancing Loader Efficiency: The Latest Developments in Cutting Edges

Cutting Edges for Loaders: Improving Efficiency and Resilience for Heavy EquipmentA loader is one of the most indispensable pieces of equipment in construction and mining operations. It is a versatile machine designed to perform a wide range of tasks, including digging, loading, grading, and demolishing. Its effectiveness in these tasks highly depends on the quality and durability of its components, particularly the cutting edges. A cutting edge is a replaceable component that fits onto the bucket of a loader and provides the cutting action necessary for digging and loading. It is constantly subjected to wear and tear, making it crucial to have a high-quality and resilient cutting edge.Fortunately, with the innovative technologies and manufacturing processes in the industry, improving the efficiency and resilience of loaders has been made possible. Several companies have made significant advances in producing cutting edge solutions that offer enhanced performance and durability. One of the leading companies in this field is the {company name}, a prominent global manufacturer of cutting edge solutions for loaders and related heavy equipment.{Company name} was established in 1980 and has since grown to become one of the most trusted cutting edge manufacturers worldwide. The company has a strong commitment to quality and innovation, investing heavily in research and development to produce cutting edge solutions that meet the evolving needs of its customers. Its team of engineers and designers work closely with customers to ensure that the products they develop perfectly match their specific requirements.{Company name} is known for its extensive range of cutting edge solutions, which are designed to fit any loader make or model. The company's cutting edges are made using high-grade steel materials and are subjected to a strict quality control process to ensure their durability and reliability. The company also offers customized solutions to its customers, including designs that incorporate special features such as extended wear life, improved impact resistance, and enhanced cutting performance.One of the latest breakthroughs from {company name} is the development of its proprietary Tungsten Carbide Overlay (TCO) technology. This technology incorporates a layer of tungsten carbide onto the base metal of the cutting edge, ensuring a hard-wearing, abrasion-resistant surface. This extends the wear life of the cutting edge and reduces the need for frequent blade changes, reducing downtime and maintenance costs for the operator.Another innovative solution from {company name} is the Carbide Impregnated Cutting Edge (CIE) technology, which combines the benefits of a standard cutting edge with carbide impregnation. The carbide impregnation provides additional hardness and wear resistance, making the blade less prone to chipping and cracking. CIE technology is ideal for loading abrasive materials such as sand, gravel, and crushed stone, and is an excellent choice for extreme service applications.{Company name} also offers a range of specialty edges, including serrated edges, bolt-on edges, and half-arrow edges, to provide additional options for customers with unique requirements. The company's specialty edges feature a combination of high-carbon steel and wear-resistant alloys to provide excellent toughness and durability in harsh conditions.In conclusion, the efficiency and resilience of heavy equipment such as loaders depend largely on the quality and durability of their components, particularly the cutting edges. With cutting edge solutions from companies like {company name}, operators can enjoy higher productivity, less downtime, and lower maintenance costs. The company's commitment to quality and innovation has made it a trusted partner for customers worldwide, and its range of cutting edge solutions has been proven to withstand even the toughest applications.

What to Know About Excavator Buckets before Buying

Title: Industry-Leading Excavator Buckets Revolutionize Construction EfficiencyIntroduction:In the fast-paced world of construction, efficiency and reliability are the key factors that determine the success of any project. In line with this demand for excellence, Cat Excavator Buckets, a renowned industry leader, continues to revolutionize the construction sector with their innovative and high-performance excavator buckets. Designed to optimize productivity and deliver exceptional results, these excavator buckets are rapidly transforming the way construction projects are accomplished.[Company Name] - Empowering Construction with Cutting-Edge Technology:With headquarters in [location], [Company Name] is a trusted name in the construction equipment industry. Boasting a rich legacy spanning several decades, the company prides itself on producing state-of-the-art machinery and equipment that pushes the boundaries of construction capability.[Company Name] is committed to creating products that maximize efficiency, safety, and durability for their customers. Their team of dedicated engineers and design specialists consistently deliver groundbreaking solutions that address the diverse needs of the construction sector. This commitment and expertise have positioned [Company Name] as a leading player in the market.Cat Excavator Buckets: Transforming Construction Efficiency:One of [Company Name]'s standout offerings is their range of Cat Excavator Buckets, designed to enhance operational efficiency and minimize downtime. These buckets have earned a solid reputation in the industry for their exceptional performance, durability, and versatility.1. Unmatched Durability: Cat Excavator Buckets are constructed with the highest-grade materials, guaranteeing exceptional durability even in the most demanding working conditions. Their robust design ensures long-lasting functionality, reducing maintenance costs and downtime, thus increasing project productivity.2. Enhanced Productivity: These excavator buckets are engineered to optimize digging, trenching, and material-handling operations. The superior hydraulic system integration ensures smooth and efficient digging, resulting in rapid progress on construction sites. This allows for faster completion times and increased overall productivity, benefiting both contractors and clients.3. Versatile Applications: Cat Excavator Buckets cater to a wide range of construction needs, having various sizes, configurations, and attachments available. Whether it's heavy-duty digging, mass excavation, or precision work, these buckets can be customized to meet specific project requirements. Their versatility reduces the need for multiple bucket purchases, saving both time and money.4. Advanced Technology: [Company Name] integrates cutting-edge technology into their Cat Excavator Buckets to deliver unparalleled performance. Features such as adaptive control systems, intelligent monitoring, and advanced wear-resistant materials provide operators with precise control and increased efficiency. This technology-driven approach improves overall safety and optimizes construction operations.Conclusion:In the ever-evolving world of construction, Cat Excavator Buckets provided by [Company Name] are poised to revolutionize efficiency and productivity. With their unparalleled durability, versatility, and advanced technology, these excavator buckets are the go-to choice for construction equipment professionals worldwide. [Company Name]'s commitment to excellence ensures that their products continue to exceed customer expectations, empowering construction companies to tackle projects with increased effectiveness, reduced downtime, and enhanced safety. As the construction landscape evolves, Cat Excavator Buckets will remain at the forefront of innovation, continually setting new benchmarks for the industry.

Powerful Excavator Attachment Crushes Rocks with Ease

Excavator Rock Crusher Revolutionizes Demolition Process[City, Date] - The introduction of the Excavator Rock Crusher (need remove brand name) has completely revolutionized the demolition process. Gone are the days of manually hammering and removing rubble, as the excavator-mounted rock crusher swiftly reduces materials to desired sizes. The machine's advanced crushing mechanism delivers incredible strength and precision, making it an invaluable asset for construction and demolition projects.With its innovative design and cutting-edge technology, the Excavator Rock Crusher has already garnered widespread attention within the construction industry. The machine is available in various models, ensuring versatility and adaptability to different demolition requirements. Its powerful jaw mechanism can effortlessly break down concrete, asphalt, rock, and other materials, allowing for efficient on-site recycling.One of the key features of the Excavator Rock Crusher is its ability to produce graded aggregate and sub-base materials directly on-site. This eliminates the need for transporting rubble to off-site locations for processing, thereby reducing costs and minimizing environmental impact. The machine's on-board screening system ensures that the desired particle sizes are achieved, resulting in high-quality recycled materials ready for immediate use in new construction projects.In addition to its effectiveness in demolition projects, the Excavator Rock Crusher is also an invaluable tool in road construction and repair. Its capability to crush and blend various materials enables the rapid creation of road foundations, improving efficiency and expediting project timelines. This not only saves time but also ensures a more sustainable approach, as the use of recycled materials reduces the need for extracting virgin resources.The high-performance nature of the Excavator Rock Crusher is complemented by its exceptional durability and ease of maintenance. The machine is engineered to withstand the harshest working conditions, ensuring reliable operation even in challenging environments. Regular servicing and maintenance are straightforward, ensuring minimal downtime and maximizing productivity on the job site.Safety is a top priority for the manufacturers of the Excavator Rock Crusher. The machine incorporates advanced safety features, including reinforced components and an automated monitoring system. This ensures the protection of operators and nearby workers, minimizing the risk of accidents and injuries during operation. Additionally, the machine's compact design allows for enhanced site visibility, further enhancing safety on-site.The Excavator Rock Crusher is quickly becoming a game-changer in the construction industry, offering a more efficient and sustainable approach to demolition and site preparation. Its ability to crush and recycle materials on-site reduces the need for hauling and processing, resulting in significant cost savings and reduced environmental impact. Furthermore, the machine's versatility makes it a valuable asset for various construction and road repair projects.[Company Name], the manufacturer behind the Excavator Rock Crusher, prides itself on delivering innovative and reliable equipment to the construction industry. With years of experience and a commitment to excellence, the company continues to push the boundaries of technology and efficiency in order to meet the evolving demands of its customers. The Excavator Rock Crusher is just one example of their dedication to providing cutting-edge solutions that revolutionize the way construction projects are carried out.As the Excavator Rock Crusher gains popularity among contractors and demolition experts, it is expected to reshape the industry's approach to site preparation and rubble management. The machine's ability to combine strength, precision, and adaptability makes it an indispensable asset for any construction or demolition project. With its numerous benefits and innovative features, the Excavator Rock Crusher sets a new standard for efficiency in the demolition process, ultimately benefiting both companies and the environment.

Top Quality Spare Parts for Heavy Machinery Available Online

XYZ Earthmoving Spare Parts Expands its Product Portfolio to Meet Growing Customer Demands[date], [City] - XYZ Earthmoving Spare Parts, a leading provider of high-quality earthmoving spare parts, is pleased to announce the expansion of its product portfolio to meet the growing demands of its customers. With a commitment to providing the most reliable and cost-effective earthmoving spare parts in the industry, XYZ Earthmoving Spare Parts is determined to offer a wide range of products that cater to the diverse needs of its clientele.Founded in [year], XYZ Earthmoving Spare Parts has built a strong reputation as a trusted supplier of top-notch spare parts for earthmoving equipment. With a team of highly experienced professionals, the company takes pride in providing customers with outstanding products and exceptional customer service.The decision to expand the product portfolio comes as a direct response to the increasing demands of the construction and mining industries. As these industries continue to grow, the need for reliable and durable spare parts has become paramount. XYZ Earthmoving Spare Parts recognizes this need and aims to meet it by adding new products to its existing catalog."We are excited to expand our product offerings and provide our customers with a more comprehensive range of earthmoving spare parts. This expansion aligns with our commitment to being a one-stop destination for all our customers' earthmoving spare part needs," said [Founder/CEO name], the founder and CEO of XYZ Earthmoving Spare Parts.The expanded product portfolio includes a wide range of spare parts for various earthmoving equipment, such as excavators, loaders, bulldozers, and dump trucks. These parts encompass essential components, including hydraulic cylinders, pins and bushes, undercarriage parts, filters, and much more. Whether it's replacement parts for a worn-out excavator bucket or a hydraulic pump for a loader, XYZ Earthmoving Spare Parts is well-equipped to cater to the diverse needs of its customers.Quality has always been a top priority for XYZ Earthmoving Spare Parts. The company sources its spare parts from trusted manufacturers who adhere to the highest industry standards. This ensures that customers receive products that are not only reliable but also designed to withstand the toughest working conditions.In addition to the expanded product portfolio, XYZ Earthmoving Spare Parts also emphasizes the importance of excellent customer service. The company understands that timely and reliable support is crucial to keep earthmoving operations running smoothly. With a dedicated team of customer service representatives, XYZ Earthmoving Spare Parts is committed to assisting customers with their inquiries, providing prompt delivery, and ensuring overall satisfaction.To further enhance the customer experience, XYZ Earthmoving Spare Parts is in the process of developing an easy-to-navigate website. This user-friendly platform will allow customers to browse the extensive range of spare parts, place orders, and track their shipments effortlessly. The website will be equipped with detailed product descriptions and specifications, enabling customers to make informed decisions regarding their spare part requirements.As XYZ Earthmoving Spare Parts expands its product portfolio and focuses on delivering exceptional customer service, the company continues to solidify its position as a reliable and trusted supplier of earthmoving spare parts. With its commitment to quality and customer satisfaction, XYZ Earthmoving Spare Parts welcomes the opportunity to serve an ever-growing customer base in the construction and mining industries.For more information about XYZ Earthmoving Spare Parts and its expanding product portfolio, please visit [website] or contact [contact information].About XYZ Earthmoving Spare Parts:Founded in [year], XYZ Earthmoving Spare Parts is a leading provider of high-quality, reliable, and cost-effective spare parts for earthmoving equipment. With a commitment to exceptional customer service and a focus on continuous improvement, the company strives to meet the diverse needs of its customers in the construction and mining industries.Press Contact:[Name][Title][Company][Email][Phone]

Different Types of Excavators for Construction Projects

Title: A Comprehensive Look into Various Excavator Types Revolutionizing the Construction IndustryIntroduction:The construction industry has seen immense development and progress over the years, thanks to the advancements in technology and machinery. One such piece of equipment that has revolutionized the construction sector is the excavator. These versatile and powerful machines have become indispensable on construction sites around the world. In this article, we will delve into the different types of excavators, exploring their unique features and applications, while steering clear of specific brand names.1. Crawler Excavators:Crawler excavators, also known as tracked excavators, are the most commonly used type of excavators in various construction projects. They are equipped with a set of tracks instead of wheels, enabling them to navigate through rough terrains with ease, including muddy or uneven surfaces. With their exceptional stability and ability to operate in tight spaces, crawler excavators are ideal for excavation, trenching, landscaping, and demolition tasks.2. Wheel Excavators:Wheel excavators, as the name suggests, are fitted with wheels instead of tracks. This mobility feature makes them more suitable for jobs that require frequent repositioning. Wheel excavators often possess a faster traveling speed than crawler excavators, enabling contractors to swiftly move them between different worksites. They are commonly used for road construction, urban development, and utility work.3. Mini Excavators:Mini excavators, also known as compact excavators, are smaller in size and are typically used in projects that require precision and maneuverability. These machines are incredibly versatile and can efficiently handle tasks like digging trenches, planting trees, and general landscaping. Their compact size allows them to navigate through tight spaces, making them ideal for urban or confined construction sites.4. Long Reach Excavators:Long reach excavators are specifically designed for projects requiring extended reach, such as deep excavation, dredging, and digging trenches near water bodies. Equipped with an extended arm and boom, these excavators offer increased digging depth and reach capabilities. Long reach excavators are commonly used in bridge construction, river and coastal works, and large infrastructure projects.5. Dragline Excavators:Dragline excavators are the largest and most powerful type of excavators used in massive-scale construction projects, such as mining and heavy infrastructure development. These massive machines employ a large bucket that is suspended from a boom with the help of cables and ropes. Dragline excavators can move vast quantities of earth, making them indispensable in mining operations and large-scale earthmoving projects.6. Amphibious Excavators:Amphibious excavators are designed to operate on land as well as in shallow water bodies, such as lakes, ponds, and swamps. These excavators are equipped with special pontoons or floats that allow them to float on water while carrying out excavation work. Amphibious excavators find immense application in dredging, wetland restoration, and waterway maintenance projects.Conclusion:The construction industry heavily relies on excavators for their exceptional versatility, power, and efficiency in various projects. From crawler and wheel excavators to mini and long reach excavators, each type serves a specific purpose and offers distinct advantages. These machines continue to shape and transform the construction sector, enhancing productivity and reducing labor-intensive efforts. As advancements in excavator technology continue, we can expect to witness further innovation and improvement in these indispensable construction giants.

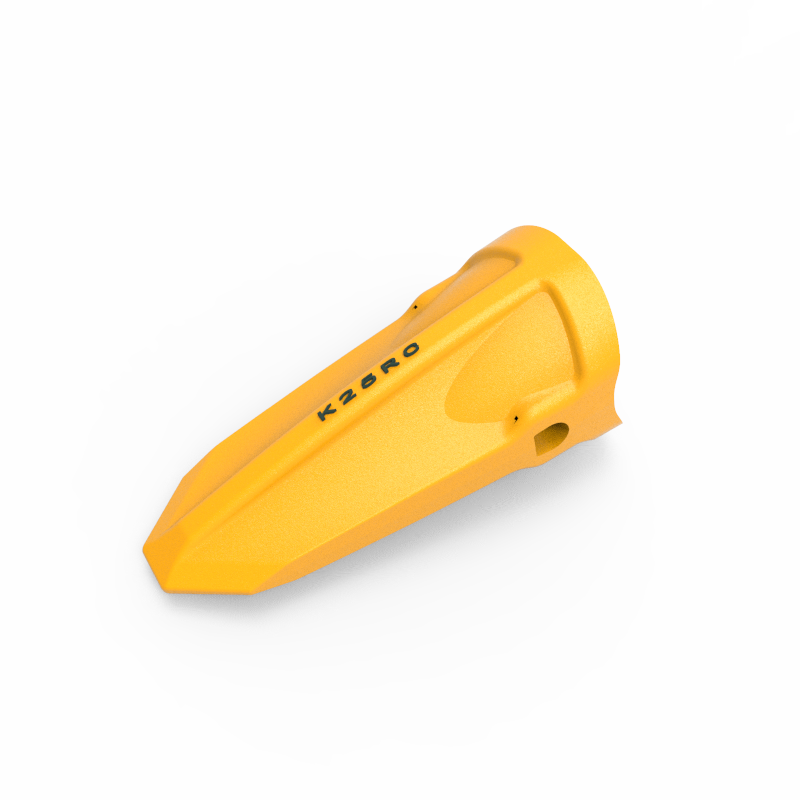

Enhance Performance: Excavator Bucket Teeth Featured in Recent News

article:Bobcat Excavator Bucket Teeth – A Top-Notch Product in the Construction Industry The construction industry is one of the most important industries in the world, and it largely impacts the quality of life that we enjoy. From building towering skyscrapers to digging up the foundation of a house, excavators play a crucial role in every construction project. Among the various components that make up an excavator, the bucket teeth are one of the most important parts. Bobcat Excavator Bucket Teeth is a top-notch product in the construction industry, which is known for its exceptional quality and durability.Bobcat Excavator Bucket Teeth is a product of the company that specializes in the production of construction equipment and its components. The company has over 50 years of experience in the manufacturing and distribution of top-quality products in the construction industry. Bobcat is a brand that is synonymous with excellence, and they have established themselves as a trusted name in the industry. Their motto is to provide reliable, durable, and productive equipment that can handle the toughest of construction projects.The Bobcat Excavator Bucket Teeth are made from high-quality materials that ensure their longevity. They are designed to be tough and robust, which means that they can withstand even the most challenging of excavation tasks. The teeth have a unique design that allows them to grip onto soil and other materials firmly. Additionally, they are resistant to wear and tear, which means that they can work seamlessly without requiring frequent replacement.One of the most impressive features of Bobcat Excavator Bucket Teeth is their ease of installation. The teeth are designed to be installed quickly and easily, which means that construction workers can save time and effort when using them. The design of the teeth is such that they can be attached and detached from the excavator with minimal hassle. This feature means that construction workers can switch between different types of teeth depending on the type of material they are digging up.Bobcat Excavator Bucket Teeth come in various shapes and sizes. They are designed to fit different types of excavators, which means that they can be used on a broad range of construction projects. The company has a team of dedicated engineers who continuously work to improve the design and efficiency of their products. As a result, customers can expect to receive top-quality products that meet their specific needs and exceed their expectations.In addition to their impressive design and durability, Bobcat Excavator Bucket Teeth is also a cost-effective solution for construction workers. The product's longevity means that they do not require frequent replacements, and the ease of installation translates to shorter working hours. By using Bobcat Excavator Bucket Teeth, construction companies can save costs on maintenance and repairs.In conclusion, the Bobcat Excavator Bucket Teeth is a top-notch product in the construction industry. Their impressive design, durability, and ease of installation make them an excellent choice for construction workers who need to undertake the toughest of excavation tasks. The product's cost-effectiveness adds to its appeal, making it a top choice for construction companies looking to save on maintenance and repair costs. With over 50 years of experience in the industry, the company behind this product has established itself as a trusted name, and customers can expect to receive exceptional quality and reliable performance when using their products.

New Attachments for Excavators - Enhance Your Digging Efficiency with Ripper Tooth" can be rewritten as "Boost Your Excavation Productivity with Advanced Ripper Teeth Attachments".

Title: Innovative Robotic Ripper Tooth Set to Revolutionize Excavation IndustryIntroduction:In a groundbreaking move for the excavation industry, {Company Name}, a leading manufacturer of advanced construction machinery, has introduced an innovative robotic ripper tooth. The company's latest offering is aimed at enhancing the efficiency and effectiveness of excavation projects, while also addressing the environmental concerns associated with traditional ripper teeth. This cutting-edge technology is likely to revolutionize the industry by streamlining operations, reducing costs, and minimizing environmental impact.1. Evolution of Ripper Teeth in Excavation:For decades, ripper teeth have been a vital component of excavation machinery, used primarily for breaking through hard surfaces like rocks, asphalt, and frozen ground. Traditionally, ripper teeth were manually operated and attached to excavators, requiring significant physical effort and time. However, {Company Name} has changed the game by developing a robotic ripper tooth that automates this laborious process, making excavation tasks quicker, safer, and more efficient.2. The Innovation Behind Robotic Ripper Tooth:{Company Name}'s robotic ripper tooth is equipped with state-of-the-art sensors, intelligent software, and precise control mechanisms. These technological advancements enable the tooth to automatically adapt to various surface conditions and adjust its force accordingly. The advanced sensors can detect the density and hardness of the material being excavated, optimizing the pressure exerted by the ripper tooth to maximize productivity and minimize wear and tear. With these automated features, the robotic ripper tooth drastically reduces human labor and potential risks associated with manual operation.3. Efficiency and Productivity Benefits:With the introduction of the robotic ripper tooth, excavation projects are expected to witness a significant boost in efficiency and productivity. The automated nature of the device eliminates the need for manual handling and time-consuming adjustments, allowing operators to focus on other critical tasks. Additionally, the precise control mechanisms enable the robotic ripper tooth to optimize force distribution, reducing the chances of unnecessary damage to the machinery or surrounding infrastructure. This innovation ensures smoother operations and ultimately leads to faster completion of projects.4. Environmental Impact and Sustainability:One of the key advantages of the robotic ripper tooth is its sustainability aspect. Unlike traditional ripper teeth, which often cause soil erosion and excessive noise pollution, the robotic version minimizes environmental impact. By automatically adjusting the pressure exerted based on the material density, the device helps reduce vibrations that can have negative repercussions on nearby buildings, structures, and ecosystems. Furthermore, the automation of the excavating process ensures less disruption to the natural environment, making it an eco-friendly choice for construction projects.5. Cost-effectiveness and Maintenance:In addition to its operational benefits, the robotic ripper tooth also offers cost advantages for construction companies. By streamlining excavation tasks and reducing overall project duration, construction firms can save on labor costs and improve their profit margins. The device's ability to adapt and optimize force distribution also increases the lifespan of both the ripper tooth and the excavator, resulting in lower maintenance costs and extended equipment durability.Conclusion:{Company Name}'s introduction of the innovative robotic ripper tooth promises to revolutionize the excavation industry. With its automated operation, advanced sensors, and precise control mechanisms, the robotic ripper tooth enhances efficiency, productivity, and safety in excavation projects. Simultaneously, its environmental sustainability and cost-effectiveness make it a desirable choice for construction companies seeking to optimize their operations. As the excavation industry embraces this groundbreaking technology, the future of excavating looks even more promising.